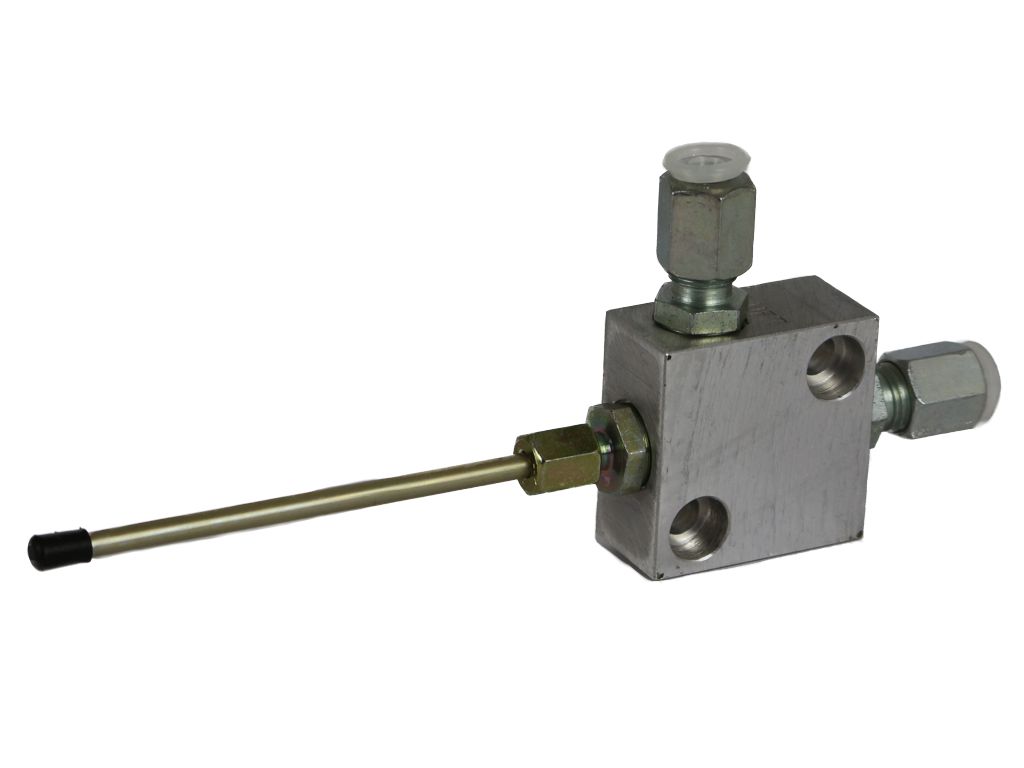

Jet Lubrication System

Application:

Jet spray systems are used with lubrication points that are difficult to access and with applications where direct installation at the lubrication point is impossible due to the installation location. This system can be implemented as a consumption lubrication system with oil.

Function:

The jet lubrication system consists of a piston pump, an electromagnet, nozzle tubes and an oil tank. Lubricant is first drawn by suction from the tank into the body of the pump. A magnet then accelerates the piston, which pumps the oil into the nozzle tubes. The nozzle tubes spray the lubricant to where it is needed. The width of the spray jet depends on the viscosity of the oil, the number of outlets, the tube lengths and the magnetic power. The nozzle tubes need to be vented to obtain a satisfactory spray pattern. Routing the lines up an incline to the outlet simplifies venting.

Benefits:

- High cycle rates are possible

- Reliable lubrication of lubrication points that are hard to access

- Monitored metering

- Up to 4 lubrication points per pump