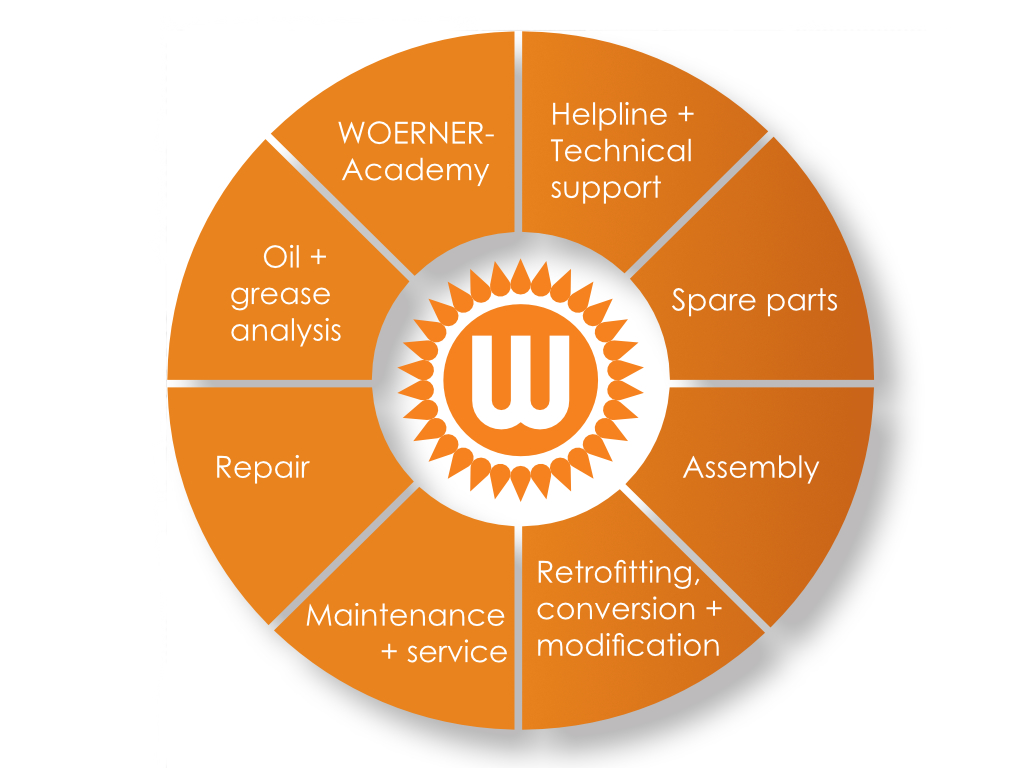

Service

WOERNER offers a series of service modules that can be combined with each other allowing you to put together an individual service and maintenance concept. Our services are ideally tailored to your needs to meet your most exacting standards.

This prevents faults on complex systems or systems that are often hard to access, avoids downtimes and lengthens maintenance intervals.

Increase and safeguard the productivity of your plant with comprehensive service modules – so that everything runs like a “well-oiled machine”.

Technical Support

Get in touch with our Technical Support team for technical questions relating to our products and applications. Our experts would be happy to answer your individual questions relating to lubrication systems and offer you advice to help you find the right solution for your application. We will solve your problems and ensure that your plant and machinery can be put back into operation as quickly as possible.

We would be happy to produce quotations for spare parts individually tailored to your requirements. This service is available to all customers during our regular business hours.

Get in Contact with us.

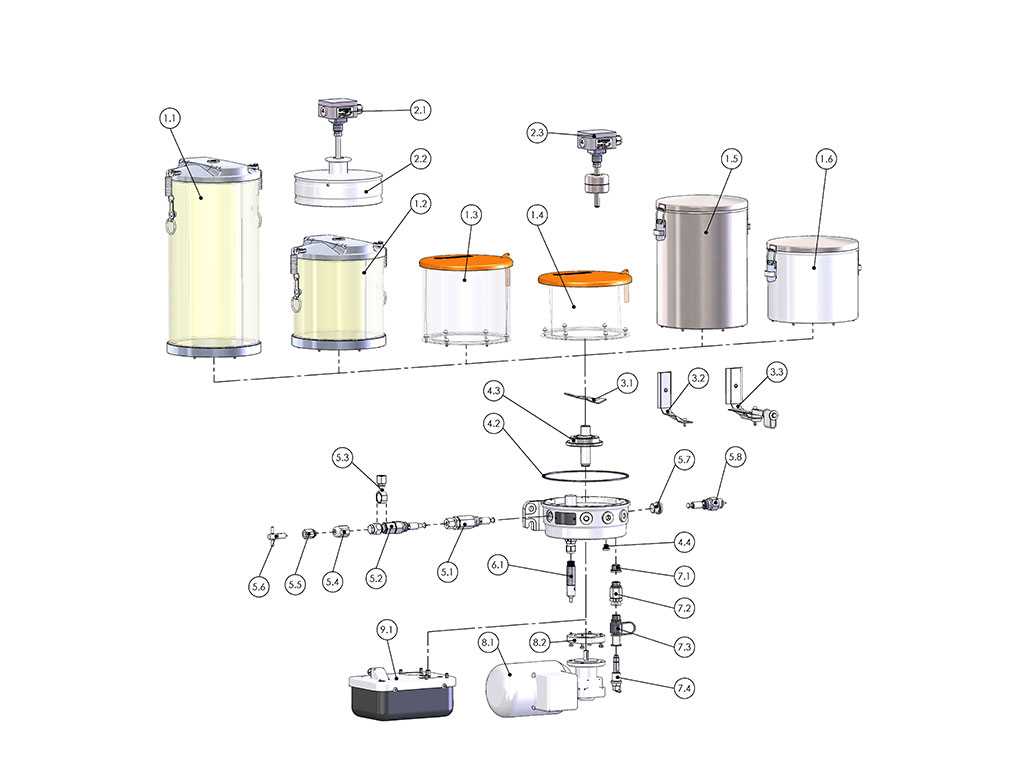

Spare parts

Our spare parts and spare parts kits are suitable for customers with their own service personnel, who have knowledge about WOERNER products and their correct operation.

Simply and quickly replace wear parts, like pump elements, seal kits etc.

Check out our spare parts data sheets at in the product range to gain an overview of the available spare parts components and take the article numbers for ordering directly from the data sheets.

Retrofits, conversions and modifications

The centralised lubrication system needs to be checked and adapted in the event of conversions, additions or modernisations to existing systems.

We are you expert partners when it comes to the individual modification of an existing system – from compact distributor systems to complex, interlinked oil lubrication circuits in paper machines or presses. Our services includes all work before, during and after the retrofit per se:

• Recording and checking of the plant and machinery

• Engineering and preparation of drawings and plans

• Re-installation of components with a connection to existing monitoring and control systems

• Recommissioning of the lubrication system for an optimum supply of lubricant to your system

Assembly

As a globally operating company, WOERNER will support you on site with the assembly of our systems. This includes all services, from planning and installation to commissioning at your preferred location.

On request, we can also deal with the integration of the electrical components into your process control systems and initial filling and commissioning. During this we also offer training of your operating personnel.

Get in Contact with us about this.

Repair

Faulty products or products no longer working properly can be returned to us for repair or inspection.

Following a thorough review of the unit, we would be pleased to send you a cost estimate for a repair or, alternatively, offer you a new unit. Please use our Returns Form (see below - Downloads) to return products to us.

With plant and equipment that cannot be transported, there is also an option to have it inspected by a service technician at your premises.

Get in Contact with us about this.

Downloads:

Preventative maintenance

The regular inspection of your centralised lubrication system can avoid unplanned downtimes and significantly increase the operational reliability of your entire plant and equipment. We offer proactive, regular inspections of your entire lubrication system.

Advice and engineering

We would be happy to advise you on all matters and questions relating to your centralised lubrication system. Among other things, this includes calculation and design of components as well as pipe and fitting materials.

The preparation of installation plans as well as the design and customer-specific development or adaptation of products and systems also forms part of our “Advice and Engineering” service area.

Oil and grease service

Incorrect filling of the centralised lubrication system tank frequently leads to malfunctions or even the failure of the affected plant. We would be happy to offer support in dealing with your WOERNER product.

On request, we will take a grease or oil sample and analyse it. We will then discuss jointly with you how we can avoid problems and thus increase the operational reliability of your system in future.

WOERNER Academy

Our product and application-specific training courses help to deepen your knowledge and provide answers to questions relating to our systems.

Whether maintenance teams or designers – we tailor the training programme to your individual needs and impart knowledge that you can use in your everyday work. Examples of courses include:

• Basic training seminar on lubrication technology

• Advanced seminars on lubrication technology

• Technology seminars (content tailored to customers)

The training courses can be held at your premises or at our head office in Wertheim. Please do not hesitate to get in Contact with us.